Balancing act

SUMMARY

Pacific Energy is built on a conviction that sustainable growth requires a balance among economic, environmental and social performance. In Canada, that balance is provided by Pacific Canbriam Energy. [Image credits: Pacific Energy]

By Dale LunanPacific Energy, the Canadian vanguard of Singapore’s RGE (Royal Golden Eagle) Group, has developed over the past two decades in a fashion that is opposite to most upstream oil and gas companies: markets came first, then production was backfilled to serve those markets.

Pacific Oil & Gas (PO&G), the predecessor of Pacific Energy, was established in 2003 as an independent resource development company focused on meeting the energy needs of North America and emerging Asian economies. Its first investments were in LNG receiving terminals and gas-fired power generating stations in China.

As part of Singapore’s RGE Group, PO&G operates as an autonomous private company, but it was RGE’s founder and chairman, Sukanto Tanoto, who looked to Canada to establish PO&G’s North American foothold.

“A big part of his business was built in the pulp and paper industry and so he spent a lot of time in Canada learning the pulp and paper industry,” Ron Bailey, Pacific Energy’s executive vice president, tells NGW in an interview. “His main purpose in business is to improve lives by developing resources responsibly. He looked at the need for energy in Asia, he looked at Canada and saw the resource potential, and that’s when he started looking – more than a decade ago – for a site to develop an LNG project.”

In 2015, PO&G purchased an abandoned pulp mill site near Squamish at the head of Howe Sound, north of Vancouver, BC. It was there that the seeds were sown for Woodfibre LNG, a 2.1mn metric tons/year liquefaction facility named after the forestry services company that originally owned the site.

The permitting process for Woodfibre LNG moved quickly. In late 2015, both the Squamish First Nation (a full regulator of the project), on whose traditional territory the project would be built, and the province of BC approved its environmental assessment certificate. A year later, the federal government issued its approval.

In November 2016, Pacific Oil & Gas authorised the funds necessary for the Woodfibre LNG project to proceed, and in 2017, a 40-year federal export licence was issued by the National Energy Board, now known as the Canada Energy Regulator.

Moving upstream

With the LNG project firmly underway, Pacific Oil & Gas turned its attention to securing natural gas supply for the project, and in 2019 it acquired Montney producer Canbriam Energy, which was established in 2007 and was producing about 200mn ft3/day of natural gas under the leadership of its CEO, Paul Myers, when PO&G took over.

“Canbriam is one of the lowest cost producers in the Montney and we look forward to partnering with Paul Myers and the entire team,” PO&G president Ratnesh Bedi said at the time. “We welcome the opportunity to work in Canada and produce some of the lowest-emission natural gas, held to the highest environmental and technical standards in the world, and share that resource to offset GHG emissions around the globe.”

Canbriam Energy was rebranded to Pacific Canbriam Energy (PCE) shortly after the acquisition, and its leadership team, still led by Myers, set out to produce important natural resources responsibly.

The company’s gas reserves were already amongst the lowest-emitting in the world, as most Montney gas is produced from newer facilities that generate low emissions from processing, but Myers and his team were spurred to make it even more sustainable, Bailey says.

“We have significant plans for growth in Canada and this is a major pillar, but we need to do this in a responsible manner.”

Community and Climate before Company

In 2021, Pacific Canbriam became the second natural gas producer in Canada and North America to earn certification under Equitable Origin’s EO100™ Standard for Responsible Energy Development.

And a few months after receiving that certification, it participated in a first-of-its-kind deal by using its certified status to sell methane performance certificates (MPCs) to industrial gas customer Skeena Bioenergy.

S&P Global Platts and Xpansiv, the global marketplace for ESG commodities, worked together to launch this innovative new way to measure and price methane performance in natural gas production. Pacific Canbriam and other natural gas providers who qualify are able to issue MPCs that register the carbon intensity of their natural gas, proving that fugitive methane emissions fall below strict, quantifiable thresholds.

“With increasing focus on where energy comes from, Pacific Canbriam Energy is proud that the origin, energy content, and methane intensity of its natural gas has been externally verified as being responsibly sourced,” Myers said of the MPC deal. “We’re excited and proud to supply MPCs to Skeena that demonstrate the exceptionally low methane intensity associated with the development of our natural gas.”

Pacific Energy’s focus on supplying low emission energy through the sustainable use of natural resources is outlined in PCE’s 2021 Report on Sustainability, which essentially extends the vision and values Canbriam held from its inception.

The right thing

“Our mission is to improve lives by developing resources responsibly, with the vision of supplying growing economies with low emission energy through the sustainable use of natural resources,” Myers writes in the report’s introduction. “We recognized that natural gas would be an important part of the global energy supply in the future and that sustainable development would not only create a competitive advantage – it is the right thing to do.”

PCE’s sustainability focus isn’t only on the direct production and use of natural gas, but filters through all aspects of the natural gas value chain, from water used in fracking operations to waste heat generated by processing produced natural gas.

Early on, it focused on water use with investments in recycling capabilities and distribution pipelines. Now, its Montney field operations are fully connected with water pipelines, over 92% of the water it uses is recycled, and it has completely eliminated the use of trucks to deliver 4.4bn litres of fluids. The end result is a 20,200 metric ton reduction in CO2-equivalent (CO2e) emissions from trucking operations.

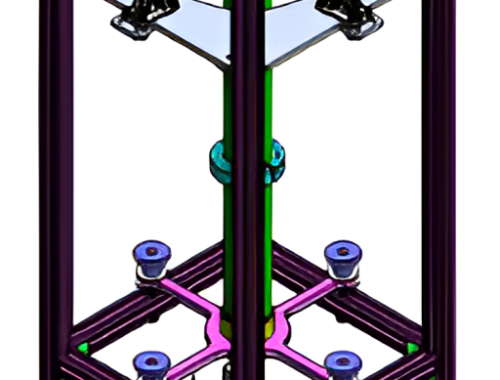

“In addition to our pipeline connected field, we utilise innovations such as waste heat recovery at our main gas plant to completely eliminate the need for gas-fired process heat, vapour recovery units to capture processing vent gas, and electrification of control systems at multi-well pads to eliminate methane-emitting pneumatic devices,” PCE says in the sustainability report.

Pacific Canbriam Energy's Altares gas plant

The Altares gas plant recycles waste heat, reducing greenhouse gas emissions by more than 6,000 metric tons/year of CO2-e of CO2e/year. PCE has also increased the use of fuel gas to displace diesel in its drilling and completions operations, with an accompanying 24% reduction in GHG emissions and the elimination of 12.6mn litres of diesel.

But it is in the key goal of reducing methane emissions that PCE’s commitment to sustainability shines, and it was that commitment that led it to pursue, and earn, certification under Equitable Origin’s EO100™ program, Myers writes.

“Pursuing Equitable Origin certification was a natural step in our evolution as a growing company and is aligned with our values. Certification has also realized new and unique opportunities, such as the generation and transaction of Methane Performance Certificates (MPCs) – tradeable instruments that unlock the market value of low methane intensity gas production. This achievement marks the beginning of a new, more transparent era of natural gas development in Canada.”

The path to net zero

Underpinning the certification are PCE’s emissions metrics. Emissions intensity has been reduced by 29% since 2014, and in 2021 was measured at 0.0125 metric tons of CO2-equivalent/barrel of oil equivalent (boe) of production (mtCO2e/boe). Methane intensity has been reduced by 48% since 2014 and was measured in 2021 at 0.0016 mtCO2e/boe.

Vapour recovery units at one gas processing plant conserve more than 13mn ft3/year of gas, eliminating 5,300 mtCO2e/year of vented emissions; both of PCE’s gas processing facilities run fully on instrument air, and 99% of its wellsite pneumatics are either zero-bleed or low-bleed; and all of PCE’s gas processing facilities and compressor stations incorporate robust leak detection and repair (LDAR) programmes.

“That is all evidence of the value we see in investing in sustainability, and we certainly look to extract some value from that, but it’s also part of our plan to grow within that framework that we find ourselves in,” Bailey says. “We have a pathway to net zero emissions – we’ll see how long it takes us to get there, but this is another step in the right direction to get there.”

The latest in a continuing series featuring the work of Gas Pathways Platform participants in advancing natural gas innovation.